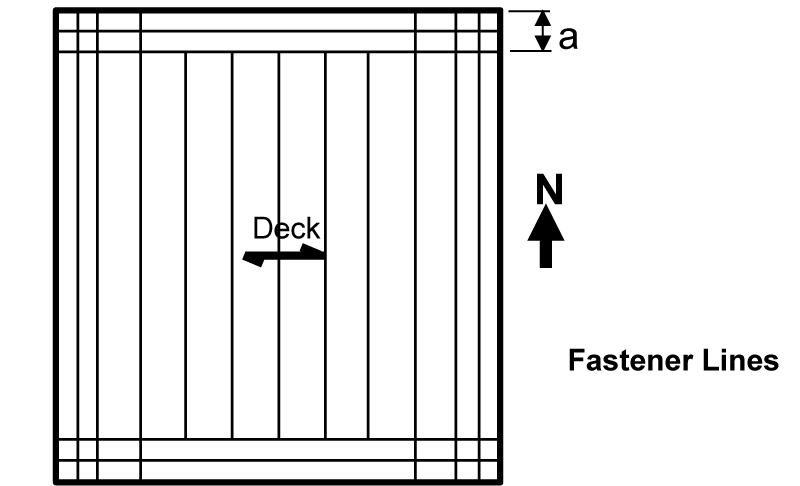

Roof Deck Fastener Layout

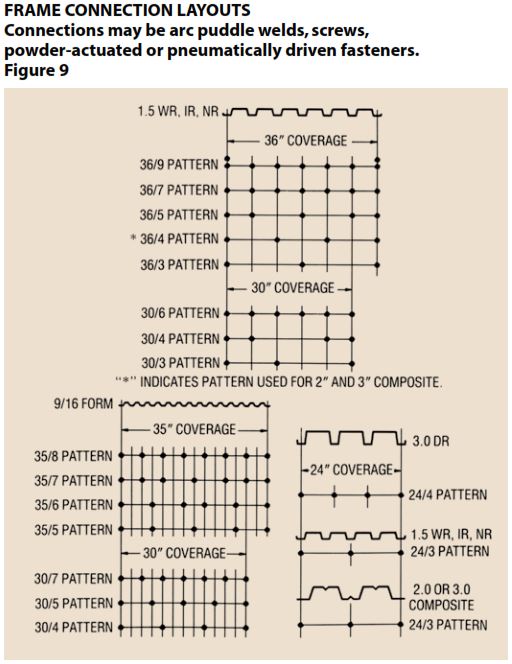

On larger structures consider zoning your roof deck connection design and select the fastening pattern to match the uplift and diaphragm demand which will vary across the floor or roof.

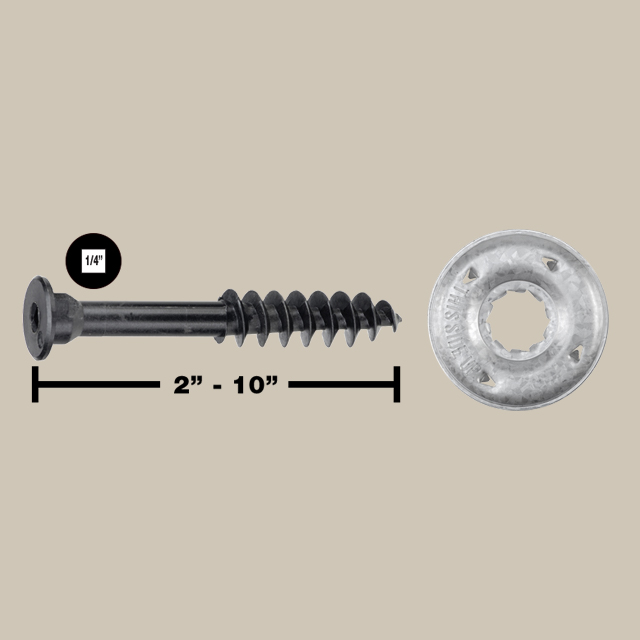

Roof deck fastener layout. End lap w valley a minimum of 12 inches. May vary based on substrate hardness na product name structural concrete fastener ultrafast metal plate lite deck. Temporarily secure valley in place with small nails or flat screws. The minimum fastener pullout resistances for specific system the information listed in the chart below is for use with the referenced roof deck fastener type minimum pullout values and required penetration depths based on fasteners type.

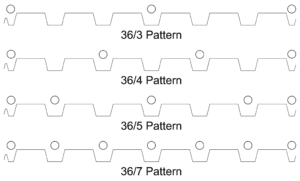

36 coverage 36 coverage 30 coverage 24 coverage 32 coverage 33 coverage 1 5 b f a vl 2vli 3vli 0 6c 1 3c 3n 1 0c 36 7 pattern 36 5 pattern 36 4 pattern 36 4 pattern 32 4 pattern 30 4 pattern 24 4 pattern 33 4 pattern. 403 279 2766 w valley applications always start w valley at eave and work towards ridge. These values are in reference to mechanically attached insulation cover boards under. Another way to provide for an economic yet well performing deck installation is to provide the deck erector with options.

This column will look at fasteners from a historical perspective since many building owners and managers have to deal with repairing or reroofing older properties at some point. Ridge cap to roof panel rib using screws at each panel rib. It can be important to recognize what the. Drive fastener perpendicular to roof deck then drive locking staple through tube disk square drive na pre drill required no no in gypsum 7 16 dia.